22 Products

Mechanic Gloves

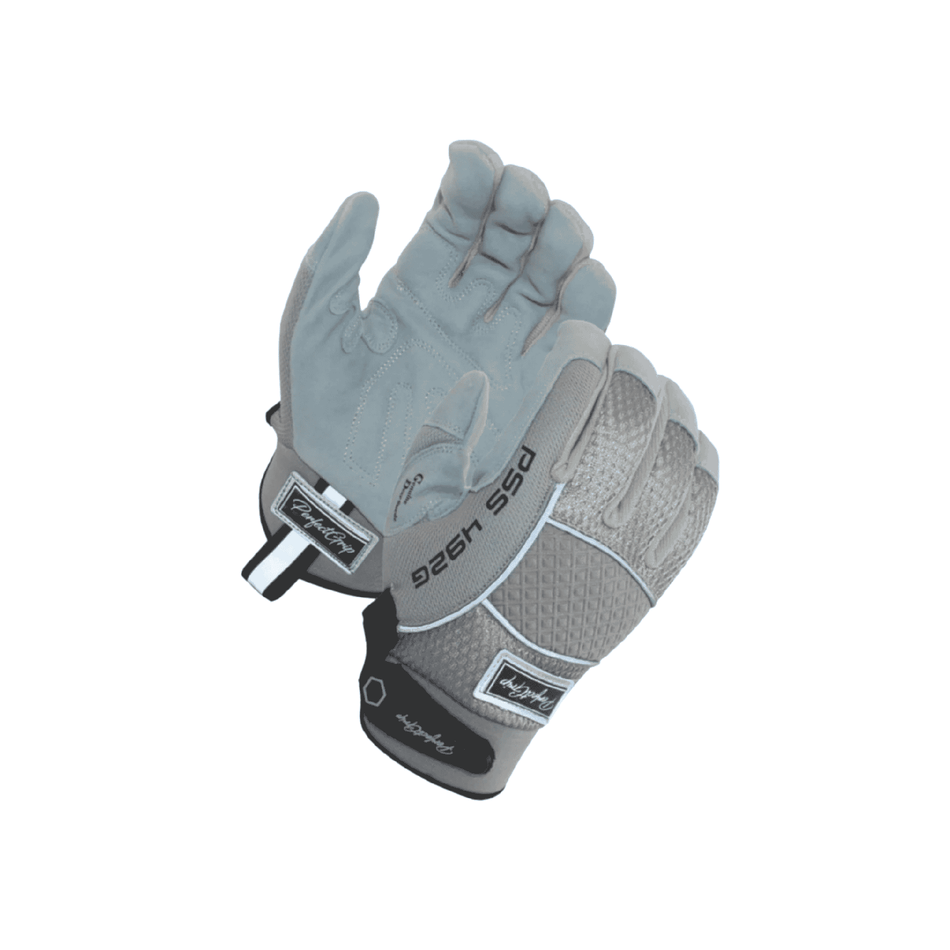

Mechanic gloves are designed to provide dexterity, grip, and protection during automotive and mechanical work.

Mechanic Gloves

Explore Mechanic Work Gloves for Protection

Mechanic gloves are essential for professionals working in automotive, aviation, and utility sectors where precision and protection go hand-in-hand. At Inland Empire Safety & Supply, we provide a carefully selected range of hand protection designed to withstand tough environments while maintaining the flexibility needed for detailed mechanical tasks. Whether you're tightening bolts, inspecting engine components, or operating tools, the right pair of gloves can improve both safety and performance.

Crafted from rugged materials like synthetic leather, nitrile, and stretch fabrics, these gloves deliver exceptional durability without sacrificing dexterity. Many styles also feature padded palms to reduce vibration and fatigue, along with breathable panels that help manage moisture during intense work. Designed for all-day comfort and secure grip, our mechanic gloves support optimal performance in demanding settings.

Mechanic Gloves Features

- Durable materials such as synthetic leather and nitrile resist abrasions and wear in mechanical environments.

- Stretch zones and ergonomic construction enhance dexterity for precise control over tools and small parts.

- Reinforced palms and knuckles provide impact protection while reducing hand fatigue during heavy-duty tasks.

- Breathable fabric panels promote airflow to keep hands dry and comfortable throughout long shifts.

- Textured or patterned grip surfaces improve handling of oily or slippery tools and components.

Mechanic Gloves Common Applications

- Automotive repair and maintenance

- Aviation inspection and servicing

- Utility and mechanical field work

- Equipment assembly and installation

- Home garage and DIY projects

From the garage to the jobsite, mechanic gloves from Inland Empire Safety & Supply deliver the protection and performance professionals rely on.